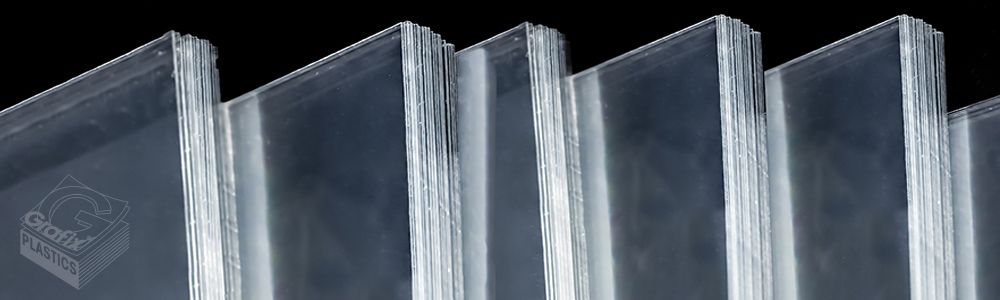

The overall majority of film we sell is Clear DuraLar. Clear DuraLar is a general purpose high clarity polyester film product line available in a range of thicknesses, and sizes, that provides a high performance, high clarity film at an attractive price point.

This product is well suited for a very diverse range of industrial applications, where a high clarity film is needed.

Features

- Archival Quality

- Dimensional Stability

- Lay Flat

- Chemical Resistance

- Consistent Color

- High Clarity

- Non-yellowing

- Heat Resistance up to 200°C

- Great electrical resistance

- Good tensile strength

- Tear Resistance

Types

Factory Treatments

- Slip Treated

- Adhesion Treated

- Anti-Static

- Wed Media Treated

- Plain

Post Coatings

- Hard Coatings

- Digital Print

- Adhesive

- Laser Release

Note: Specific types of DuraLar can result in specific minimum quantity orders.

Stock

Looking for something fast? We always have Clear DuraLar in stock!

Raw material sizes

Master Stock:

| Thickness | 20+" | 27"+ | 40"+ | 50"+ | 54"+ | 60"+ | Other | ||

|---|---|---|---|---|---|---|---|---|---|

| .001"/25um | C | S | C | C | S | C | C | ||

| .002"/50um | S | C | S | S | C | C | C | ||

| .003"/75um | S | C | S | S | C | C | C | ||

| .004"/100um | S | C | S | S | C | C | C | ||

| .005"/125um | S | C | S | S | C | C | C | ||

| .007"/170um | S | C | S | S | C | C | C | ||

| .010"/250um | S | C | S | S | C | C | C |

S=Stock item

C=Custom order (may result in min. order quants.)

Finished goods stock sizes

Sheets

| 9×12″ | 12×18″ | 18×24″ | 20×25″ | 20×27″ | 20×50″ | 24×36″ | 25×40″ | 27×40″ | 30×40″ | 36×48″ | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clear | ||||||||||||

| .002″/50um | • | • | • | • | ||||||||

| .003″/75um | • | • | • | • | ||||||||

| .004″/100um | • | • | • | • | • | |||||||

| .005″/125um | • | • | • | • | ||||||||

| .007″/175um | • | • | • | • | ||||||||

| .010″/250um | • | • | • | • | ||||||||

| .015″/325um | • | • | • | • | • | |||||||

| .020″/250um | • | • | • | • | • | |||||||

| Matte | ||||||||||||

| .005″/125um | • | • | • | • | ||||||||

| Wet Media | ||||||||||||

| .004″/100um | • | • | • | |||||||||

Rolls

20″ x 12′ | 20″ x 25′ | 20″ x 50′ | 20″ x 100′ | 27″ x 12′ | 27″ x 25′ | 27″ x 50′ | 27″ x 100′ | 40″ x 12′ | 40″ x 25′ | 40″ x 50′ | 40″ x 100′ | 50″ x 12′ | 50″ x 25′ | 50″ x 50′ | 50″ x 100′ | 54″ x 12′ | 54″ x 25′ | 5″n x 50′ | 54in x 100′ |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clear | |||||||||||||||||||||

| .001″/25um | • | • | • | • | • | • | • | • | |||||||||||||

| .002″/50um | • | • | • | • | • | • | • | • | |||||||||||||

| .003″/75um | • | • | • | • | • | • | • | • | • | • | • | • | |||||||||

| .004″/100um | • | • | • | • | • | • | • | • | • | • | • | • | |||||||||

| .005″/125um | • | • | • | • | • | • | • | • | • | • | • | • | |||||||||

| .007″/175um | • | • | • | • | |||||||||||||||||

| .010″/250um | • | • | • | • | |||||||||||||||||

| Matte | |||||||||||||||||||||

| .005″/125um | • | • | • | • | • | • | • | • | |||||||||||||

| Wet Media | |||||||||||||||||||||

| .004″/100um | • | • | • | • | • | • | • | • | |||||||||||||

Packs

| 8.5×11″ | 9×12″ | 10×12″ | 11×14″ | 11×17″ | 14×17″ | 18×24″ | ||

|---|---|---|---|---|---|---|---|---|

| Clear | ||||||||

| .002″/50um | • | • | • | • | ||||

| .003″/75um | • | • | • | • | ||||

| .004″/100um | • | • | • | • | ||||

| .005″/125um | • | • | • | • | ||||

| .007″/175um | • | • | • | • | ||||

| .010″/250um | • | • | • | • | ||||

| Matte | ||||||||

| .005″/125um | • | • | • | • | ||||

| Wet Media | ||||||||

| .004″/100um | • | • | • | • | ||||

Specs

Properties are based on .001″/24um general use Duralar polyester film. Properties of other gauges and finishes of DuraLar polyester film can vary.

General DuraLar Spec Sheet

| Film Property | Value | Units | Test Method | ||

|---|---|---|---|---|---|

| Physical Properties | |||||

| Tensile Strength (MD) | 28,000 | psi | ASTM D 882 | ||

| Tensile Strength (TD) | 34,000 | psi | ASTM D 882 | ||

| Strength Elongation MD | 15,000 | psi | ASTM D 882 | ||

| Strength F-5 TD | 14,000 | psi | ASTM D 882 | ||

| Modulus MD | 710,000 | psi | ASTM D 882 | ||

| Modulus TD | 740,000 | psi | ASTM D 882 | ||

| Elongation MD | 115 | % | ASTM D 882 | ||

| Elongation TD | 92 | % | ASTM D 882 | ||

| Density | 1.39 | g/cc | ASTM D 1505 | ||

| Viscosity | 0.56 | dL/g | ASTM D 4603 | ||

| Electrical Properties | |||||

| Dielectric Strength | |||||

| AC, 20°C, .00092″ | 7,000 | volts/mil | ASTM D 149-64 | ||

| Dielectric Constant | |||||

| 25°C, 1 kHz | 3.2 | ASTM D150-81 | |||

| Dissipation Factor | |||||

| 25°C, 1 kHz | 0.005 | ASTM D150-65 | |||

| Volume Resistivity 25°C | 1.00E+19 | ohm-cm | ASTM D257-78 | ||

| Corona Threshold | 425 | V-AC | ASTM D2275-80 | ||

| Thermal Properties | |||||

| Melt Point | 200 | ||||

| Service Temperature Range | -70-150 | C | |||

| Dimensional Stability | |||||

| at 105° MD | 0.6 | % | Measured Shrinkage | ||

| at 105° TD | 0.9 | % | Measured Shrinkage | ||

| at 150° MD | 1.8 | % | Measured Shrinkage | ||

| at 150° TD | 1.1 | % | Measured Shrinkage | ||

| Specific Heat | 0.28 | ||||

| Thermal Expansion | 1.7×10-5 | ASTM D 696 | |||

| Optical Properties | |||||

| Transmission Visible | > 88 | % | |||

| Transmission Near IR | >80 | % | |||

| Haze | <1 | % | |||

| Refractive Index | 1.65 | RI | |||

| Chemical Properties | |||||

| Resistance by Class | |||||

| Acids | Good | ||||

| Bases | Good | ||||

| Solvents | Excellent | ||||

| Detergents | Excellent | ||||

| Oils | Good | ||||

| Permeability | |||||

| Water Vapor | 0.1 | g/100 in2/24hr. | ASTM E-96 | ||

| Carbon Dioxide | 16 | g/100 in2/24hr. | ASTM D1434-58 | ||

| Moisture Absorption | <.8 | % | ASTM D-570-63 | ||

| Stain Resistance | Most Household Agents & Chemicals | ||||

For more specific questions regarding DuraLar Film, please contact your sales representative today!

Important Notice: Grafix makes no warranties, express or implied, including but not limited to any implied warranty of merchantability of fitness for a particular purpose. The user is responsible for determining whether the Grafix product is fit for a particular purpose and suitable for the user’s method of application. Please remember that many factors can affect the use and performance of a Grafix Plastics film product in a particular application. Given the variety of factors that can affect the use and performance of a Grafix product, some of which are uniquely within the user’s knowledge and control, it is essential that the user evaluate the Grafix product to determine whether it is fit for a particular purpose and suitable for the user’s method of application.

Limitation of Remedies and Liability: If the Grafix product is proven to be defective, THE EXCLUSIVE REMEDY, AT GRAFIX’S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OF OR TO REPAIR OR REPLACE THE DEFECTIVE GRAFIX PRODUCT. Grafix shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including, but not limited to, contract, negligence, warranty or strict liability.

Safety

- DEHP, DBP and BBP free. Contact us for more details

- RoHS Compliant

- Meets MilSpec L-P-377C, types 1-4

Our experts are ready to help make your job easy! Please contact us with your requirements today by starting an inquiry.