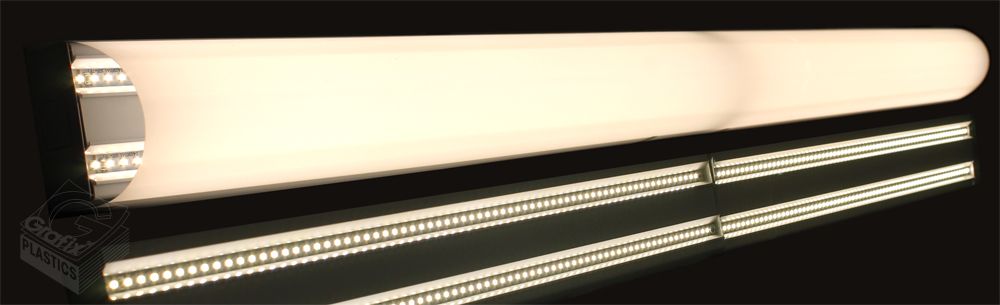

OptiGrafix™ Light Diffuser Films are one- or two-side diffuser film products designed to break up and distribute light evenly.

They can be used for a variety of different lighting applications like electronic displays and signs, LED-based lighting systems, fluorescent-based lighting systems, and printed signage.

Features

- Thin polymer film construction

- Uniform surface properties (matte or gloss)

- Available in a several grades

- Flexible & bendable

- Specific grades compatible with polarized light

- Excellent dimensional stability

- Commercially available

- Economical

Diffuser Film Attributes

| DFPM | DFPMHT | DFMM | DFIM | LBMT | LBOM | |

|---|---|---|---|---|---|---|

| Anti-Static | Yes | Yes | Yes | No | No | No |

| Rugged PET Base | Yes | Yes | Yes | Yes | LB Grade | LB Grade |

| Commercially Available | Yes | Yes | Yes | Yes | Yes | Yes |

| Roll Stock | Yes | Yes | Yes | Yes | Yes | Yes |

| Sheet Stock | Yes | Yes | Yes | Yes | Yes | Yes |

| Low Birefringence | No | No | No | No | Yes | No |

| Max Width Custom | 60″ / 1525mm | 60″ / 1525mm | 60″ / 1525mm | 60″ / 1525mm | ||

| Max Width (Stock) | 42″ / 1067mm | 42″ / 1067mm | 42″ / 1067mm | 50″ / 1270mm | 50″ / 1270mm |

Grades

| Grades: | DFPM | DFPMHT | DFMM | DFIM | LBMT | LBOM |

|---|---|---|---|---|---|---|

|  |  |  |  |  |

|

| Finish | 1/Side Matte | 1/Side Matte | 2/Side Matte | 2/Side Matte | 1/Side Matte | 1/Side Matte |

| Color | Clear / White | Clear / White | Clear / White | Clear / White | Clear | White |

| Gloss (gu) S1/S2 | 4/52 | 9/50 | 4/4 | 40/40 | 14/93 | 7/82 |

| Transmission | 85% | 89% | 75% | 67% | 92% | 55% |

| Haze | 90% | 85% | 90% | 90% | 68% | 95% |

| Min. Stock Thickness | .003" / 75um | .003" / 75um | .003" / 75um | .002" / 50um | .003" / 75um | .005" / 125um |

| Max. Stock Thickness | .007" / 175um | .007" / 175um | .007" / 175um | .005" / 125um | .004" / 100um | .005" / 125um |

| Custom Thickness | up to.010" / 200um | up to.010" / 200um | up to.010" / 200um | n/a | .005" - .020" | .005" - .020" |

DFPM Grade Diffusers are translucent, 1/side matte, 1/side luster film that can be used under a variety of lighting conditions. The luster surface provides a bit of specular back reflection. This grade is made from a rugged PET base film, and is available in a variety of thicknesses and sizes.

DFPMHT Grade Diffusers are a slightly higher-transmission version of DFPM Grade Diffuser Film, a is a 1/side matte, 1/side gloss film that can be used under a variety of lighting conditions. The gloss surface provides a specular back reflection. This grade is made from a rugged PET base film, and is available mostly in .003″ and .004″. Other thicknesses are custom.

DFMM Grade Diffusers are translucent, 2/side matte film that can be used under a variety of lighting conditions except polarized light. Two layers of matted finish provide maximum diffusion. Made from a rugged PET base film, DFMM is available in a variety of thicknesses and sizes.

DFIM Grade Diffusers are translucent, internal matte film that can be used under a variety of lighting conditions except polarized light. 2/side luster, internal matted finish provides maximum diffusion at an economical price point. This grade is made from a rugged PET base film, and is available in a variety of thicknesses and sizes.

LBMT Grade Light Diffuser Film is a 1/side matte, 1/side gloss clear film. Its low, uniform birefringent properties make it ideal for diffusing polarized light. This is a lighter diffusion product with maximum transmission – more aggressive than anti-glare film, but not as hazy as our other products. And it can also be thermoformed!

LBOM Grade Light Diffuser Film is a 1/side matte, 1/side gloss clear film. This ultra-bright white film can be printed with solvent and UV inkjet, as well as conventional printing methods, for use in back-lit signage. Its bright white opalescent quality really makes colors pop! It is also a very aggressive diffuser. And it can be thermoformed!

Stock

Raw material stock:

| Grades: | DFPM | DFPMHT | DFMM | DFIM | LBMT | LBOM |

|---|---|---|---|---|---|---|

|  |  |  |  |  |

|

| Min. Stock Thickness | .003″ / 75um | .003″ / 75um | .003″ / 75um | .002″ / 50um | .003″ / 75um | .005″ / 125um |

| Max. Stock Thickness | .007″ / 175um | .004″ / 100um | .007″ / 175um | .005″ / 125um | .004″ / 100um | .005″ / 125um |

| Custom Thickness | .010″ / 200um | .005″ / 125um | .010″ / 200um | .005″ – .020″ | ||

| Finish | 1/Side Matte | 1/Side Matte | 2/Side Matte | 2/Side Matte | 1/Side Matte | 1/Side Matte |

| Color | Clear / White | Clear / White | Clear / White | Clear / White | Clear | White |

| Max Width Custom | 60″/1525mm | 60″/1525mm | 60″/1525mm | 60″/1525mm | ||

| Stock Roll Width | 36″, 42″/ 916, 1067mm | 36″, 42″/ 916, 1067mm | 36″, 42″/ 916, 1067mm | 50″/1270 | 52″/1270 |

Custom widths are available on a custom order basis – minimum quantities will apply.

Finished goods stock:

Sheets

| Size: | 8.5 x 11″ | 11 x 17″ | 12 x 18″ | 17 x 22″ | 18 x 24″ | 20 x 25″ | 20 x 50″ | 22 x 34″ | 24 x 36″ | 25 x 40″ | 30 x 40″ | 30 x 42″ |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DFPM | |||||||||||||

| .003″/75um | • | • | • | • | • | • | • | • | |||||

| .004″/100um | • | • | • | • | • | • | • | • | |||||

| .005″/125um | • | • | • | • | • | • | • | • | |||||

| .007″/175um | • | • | • | • | • | • | • | • | |||||

| DFMM | |||||||||||||

| .003″/75um | • | • | • | • | • | • | • | • | |||||

| .004″/100um | • | • | • | • | • | • | • | • | |||||

| .005″/125um | • | • | • | • | • | • | • | • | |||||

| .007″/175um | • | • | • | • | • | • | • | • | |||||

| LBMT | .003″/750um | • | • | • | • | • | • | ||||||

| .005″/100um | • | • | • | • | • | • | |||||||

Rolls

Grade | 25″ x 12′ | 25″ x 25′ | 25″ x 50′ | 25″ x 100′ | 36″ x 10yds | 36″ x 20yds | 36″ x 50yds | 42″ x 10yds | 42″ x 20yds | 42″ x 50yds | 50″ x 12′ | 50″ x 25′ | 50″ x 50′ | 50″ x 100′ |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DFPM | |||||||||||||||

| .003″/75um | • | • | • | • | • | • | |||||||||

| .004″/100um | • | • | • | • | • | • | |||||||||

| .005″/125um | • | • | • | • | • | • | |||||||||

| .007″/175um | • | • | • | • | • | • | |||||||||

| DFMM | |||||||||||||||

| .003″/75um | • | • | • | • | • | • | |||||||||

| .004″/100um | • | • | • | • | • | • | |||||||||

| .005″/125um | • | • | • | • | • | • | |||||||||

| .007″/175um | • | • | • | • | • | • | |||||||||

| LBMT | .003″/750um | • | • | • | • | • | • | • | • | ||||||

| .005″/100um | • | • | • | • | • | • | • | • | |||||||

Not sure you’re seeing what you need? Please start an inquiry today!

Specs

Typical Properties based on .003″ of DFPM, DFMM and LBMT, Other thicknesses can vary.

| Film Type: | DFPM-DFMM | LBMT-LBOM | |||||

|---|---|---|---|---|---|---|---|

| Value | Value | Units | Test Method | ||||

| Physical Properties | |||||||

| Tensile Strength (MD) | 28000 | 14400 | psi | ASTM D 882 | |||

| Tensile Strength (TD) | 34000 | 14400 | psi | ASTM D 882 | |||

| Strength Elongation MD | 15000 | 34.394625 | psi | ASTM D 882 | |||

| Strength F-5 TD | 14000 | psi | ASTM D 882 | ||||

| Modulus MD | 710000 | 360000 | psi | ASTM D 882 | |||

| Modulus TD | 740000 | 360000 | psi | ASTM D 882 | |||

| Elongation MD | 115 | 0.45 | % | ASTM D 882 | |||

| Elongation TD | 92 | 0.25 | % | ASTM D 882 | |||

| Electrical Properties | |||||||

| Dielectric Strength | |||||||

| AC, 20°C, .00092″ | 7000 | 15000 | volts/mil | ASTM D 149-64 | |||

| Dielectric Constant | |||||||

| 25°C, 1 kHz | 3.2 | n/a | ASTM D150-81 | ||||

| Dissipation Factor | |||||||

| 25°C, 1 kHz | 0.005 | n/a | ASTM D150-65 | ||||

| Volume Resistivity 25°C | 1.0E+19 | 5.1E-13 | ohm-cm | ASTM D257-78 | |||

| Corona Threshold | 425 | n/a | V-AC | ASTM D2275-80 | |||

| Thermal Properties | |||||||

| Melt Point | 200 | 120 | °C | ||||

| Service Temperature Range | -70-150 | -70-110 | C | ||||

| Dimensional Stability | |||||||

| at 105° MD | 0.6 | 1.15 | % | Measured Shrinkage | |||

| at 105° TD | 0.9 | 1.15 | % | Measured Shrinkage | |||

| at 150° MD | 1.8 | n/a | % | Measured Shrinkage | |||

| at 150° TD | 1.1 | n/a | % | Measured Shrinkage | |||

| Chemical Properties | |||||||

| Resistance by Class | |||||||

| Acids | Good | Good | |||||

| Bases | Good | Fair | |||||

| Solvents | Excellent | Poor | Polar Solvents only | ||||

| Detergents | Excellent | Good | |||||

| Oils | Good | Good | |||||

| Permiability | |||||||

| Water Vapor | 0.1 | 22 | g/100 in2/24hr. | ASTM E-96 | |||

| Carbon Dioxide | 16 | n/a | g/100 in2/24hr. | ASTM D1434-58 | |||

For more specific questions regarding Grafix Drafting Film, please contact your sales representative today!

Important Notice: Grafix makes no warranties, express or implied, including but not limited to any implied warranty of merchantability of fitness for a particular purpose. The user is responsible for determining whether the Grafix product is fit for a particular purpose and suitable for the user’s method of application. Please remember that many factors can affect the use and performance of a Grafix Plastics film product in a particular application. Given the variety of factors that can affect the use and performance of a Grafix product, some of which are uniquely within the user’s knowledge and control, it is essential that the user evaluate the Grafix product to determine whether it is fit for a particular purpose and suitable for the user’s method of application.

Limitation of Remedies and Liability: If the Grafix product is proven to be defective, THE EXCLUSIVE REMEDY, AT GRAFIX’S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OF OR TO REPAIR OR REPLACE THE DEFECTIVE GRAFIX PRODUCT. Grafix shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including, but not limited to, contract, negligence, warranty or strict liability.

Safety

- DEHP, DBP and BBP free. Contact us for more details

- RoHS Compliant. Contact us for more details

Ready to get specific? Please contact us with your diffuser film requirements today by clicking the start an inquiry button.

Visit our OptiGrafix™ products page for more on the OptiGrafix family of optical-quality polymer film products and film-related production services.